Door Closers

A door closer is a mechanical spring and pinion device designed to automatically close a door using hydraulics. Although a door closer can be defined more loosely as any device that automatically closes a door. A door closer is comprised of a rack and pinion design and spring inside of a aluminum cast housing. The aluminum cast body of the door closer is surface mounted to the door frame directly above the hinge side of the door and the door closer arm is attached to the door. As the door opens the door closer arm moves towards the door hinge, rotating the door closer spindle, moving the rack and pinion so that it compresses the tempered steel spring inside of the door closer body housing. When the door is in the full open position, the door closer device is at maximum potential energy as the door closer's internal spring is completely compressed. When the pedestrian passes through the doorway, the door closer spring decompresses to it's original length, creating kinetic energy allowing the door to close. Door closers use a combination of spring force and hydraulics in order to regulate the closing speed of the door. Inside of the closer body, is hydraulic fluid, or oil, which lubricates the bearings and seals of the door closer, but also controls the closing and latch speed using adjustable valve controls.

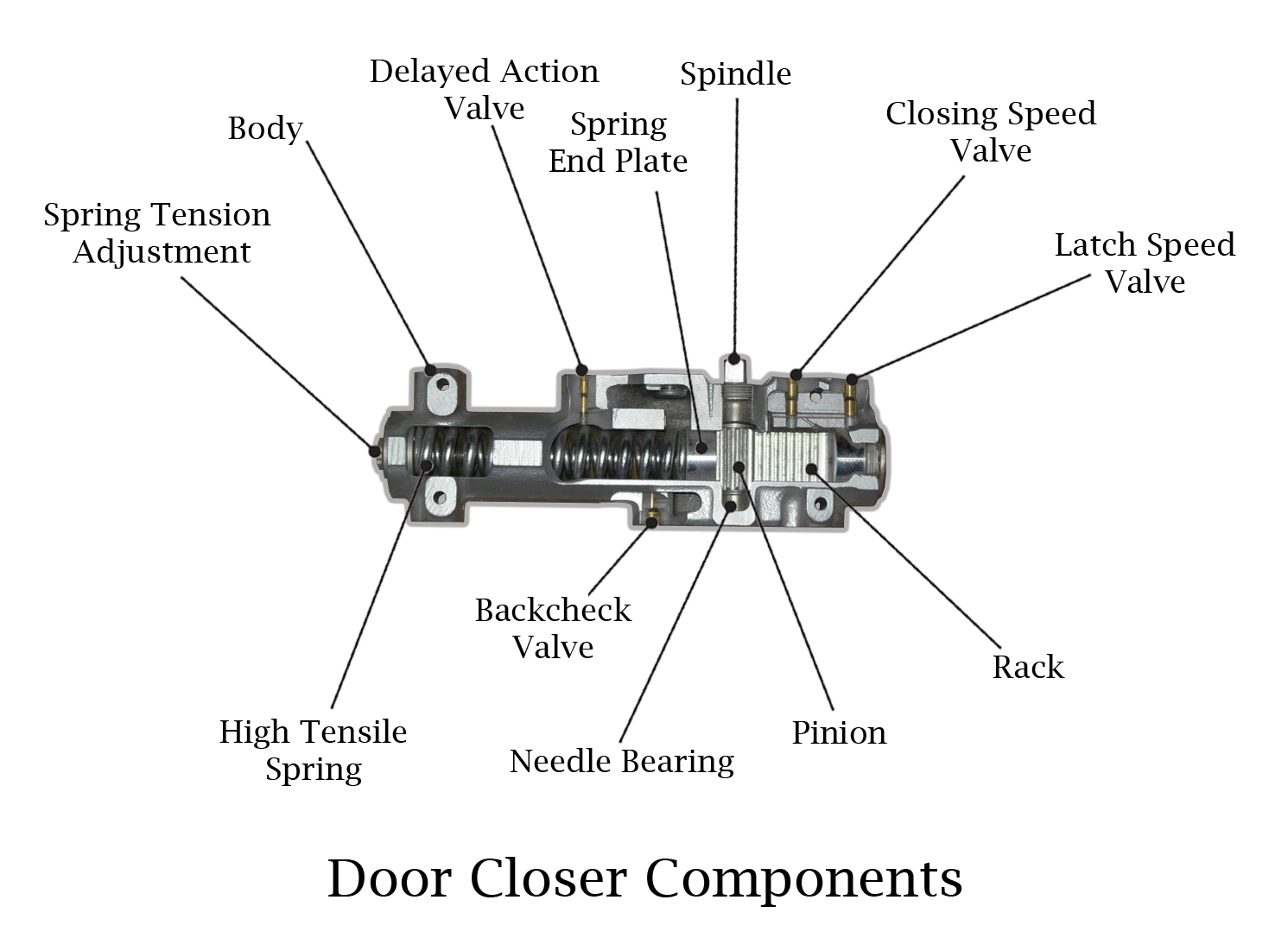

Anatomy Of A Door Closer

Although a door closer may seem like a simple device at first glance, it is actually a complex combination of mechanical parts working together to convert potential energy to kinetic energy. The illustration below shows the components that make up a door closer.

![]() Heavy Duty Cast Body

Heavy Duty Cast BodyThis is the housing that holds the internal components of the door closer. The housing is a very important component of a door closer because it holds the internal hydraulic fluid and is often under pressure when the door closer is under a load or stress ie; when the door is in the full open position. The material of the door closer body varies from aluminum to heavy duty cast steel.

Arm SpindleThe spindle is a broad term for the heat treated alloy steel rod assembly that sits vertically in the door closer body. The spindle is a crucial part of the door closer as it includes the pinion gear located at the center of the spindle.

Rack and Pinion The rack refers to saw tooth shaped track that sits inside the door closer body and sits against the door closer spring. The pinion is the middle gear portion of the entire spindle assembly which sits perpendicular to the rack and meshes with it perfectly inside of the door closer body. When the door opens, the arm spindle/pinion gear rotates, causing the rack to slide and move. As the rack slides and moves it compresses the door closer spring, creating potential energy.

Needle BearingsHeavy duty needle bearings are located at the top and bottom portion of the arm spindle; directly above and below the pinion gear. They provide stability and durability each time the arm spindle rotates from the door opening or closing. The needle bearings keep the rotation of the arm spindle tight with little to no slop and also helps reduce friction.

SpringThe door closer spring is constructed from high tensile oil tempered steel. Door closer springs have to be extremely durable, as they must constantly compress when the door opens, or decompress to it's original shape when the door closes.

![]()

Door Closer Adjustments

All commercial door closers are hydraulic, meaning they transmit power by the pressurization of liquids. Yes, hydraulic door closers do transmit power by compressing a spring, however inside of the closer body is an oil reservoir filled with hydraulic dampening fluid or an oil type substance. The closer body is completely sealed with o-rings and full of oil. The spring and rack (also referred to as a piston) divides the oil reservoir so that there is oil on the spring side of the closer body as well as oil on the rack side. As a door opens, the door closer spring compresses, creating more space on the rack side and less space on the spring side, as this happens the oil on the spring side rushes into the new found space on the rack side. Pressure is maintained through the entire process. As the door closes, the spring decompresses, creating more space on the spring side and less space on the rack side, causing the oil to rush back into the spring side. Within the oil reservoir are valves strategically placed, which regulate through small channels how much oil is able to pass from the spring side to the rack side. These valves are the adjustment valves and can be tightened to limit the amount of oil that passes through the channel or loosened to increase the amount of oil passing through the channel. As an example, you may have come across a broken door closer that is leaking oil and causes the door to slam shut. This is because the door closer body is no longer pressurized with oil since it has leaked out, so therefore there is no speed regulation, causing the door to slam from the closing spring. Likewise this is the same reason that if you unscrew an adjustment valve to far, oil will leak out of it. Once this happens, the door closer is no longer pressurized, and is unusable.

![]()

The hydraulic regulation valves control various speeds at different parts of the door opening and closing cycle. A typical door closing cycle and opening cycle is illustrated below. The closing cycle is made up of three main door speeds: delayed action, closing speed, and latch speed. While the opening cycle only has one adjustable door speed known as backcheck.

![]() Closing Speed Valve (Standard)

Closing Speed Valve (Standard)The closing speed valve is standard on all door closers and is sometime referred to as the main speed control. It is the speed adjustment from 75 degrees to 10 degrees of the closing cycle. On the above illustration it is listed as "C." The closing speed adjustment can be increased for a faster closing speed by turning the closing speed valve counter-clockwise. For a slower closing speed the valve can be turned clockwise.

Latch Speed Valve (Standard)The latch speed valve is also standard on all door closers. This valve regulates the speed of the latch portion of the closing cycle, which is 10 degrees to 0 degrees. It is labeled on the above illustration as "L." The latch speed is a crucial adjustment because it ultimately controls the speed right before the door closes. When the latch is adjusted correctly, the door will never slam shut. To increase the latch speed, the valve can be turned counter-clockwise. To decrease the latch speed, the valve can be turned clockwise.

![]() Delayed Action Valve (Optional)

Delayed Action Valve (Optional)Delayed action speed is also loosely referred to as hold open time. This valve regulates the speed of the closing cycle from the 90 degrees to 75 degrees. It is labeled on the illustration above as "D". Essentially it controls how long the door remains open before it begins closing. Delayed action is not a standard option, but an add on requiring an additional cost. Still, it is a great feature to have, because when adjusted properly the door can remain open for as long as 30 seconds, making it great for the elderly or pedestrians with disabilities.

![]() Back Check Valve (Optional)

Back Check Valve (Optional)The backcheck on a door closer regulates the opening speed during the opening cycle from 75 degrees to 90 degrees. This feature sometimes comes standard on door closers, however if not, it is always recommended to add it. The reason being, is that the backcheck feature is one of the most cost saving add on's to save your door from future repairs due to damage. The backcheck helps reduce the damage from winds catching the door and slamming the door open roughly, or from pedestrians abusively opening the door. With the backcheck valve, the door is unable to "slam" open which not only saves the door, but also the door hinges, the wall near the door, the door frame, and much more. Remember, a door is an investment, it is much more inexpensive to add the backcheck feature to a door closer, rather than have to purchase a whole new door in the future due to wind or abusive pedestrians ripping the door open.

![]() Spring Power Adjustment

Spring Power AdjustmentDoor closers are offered in two main spring types: fixed or adjustable.

Fixed SpringIf a door closer's spring is fixed it typically specified by the manufacturer and is often rated from size 1, 2, 3, 4, 5, or even 6. As the spring size increases, it indicates a larger and stiffer spring, which can be used on larger doors. As an example a door closer with a spring size of 1 would only be good for a 32 inch wide interior door, where as a door closer with a spring size of 5 would be good for a 54 interior wide door or a 48 exterior door. With

fixed spring door closers you are unable to change the spring size on the door closer. You would have to know the door size you plan to use the door closer on, and make sure you order the correct size spring door closer. For this reason fixed spring door closers are often not as popular as adjustable spring door closers.

Adjustable SpringDoor closers with adjustable springs are the most popular. An

adjustable spring door closer has an adjustment nut at the end of the door closer which allows the installer to tighten or loosen the nut in order to adjust the spring size/tension. The illustration below shows an example of the spring adjustment. An adjustable spring door closer's main advantage is it's versatility since it can be used on any size door.

![]()

Door Closer Installation Types

Standard InstallationStandard installation is the most popular. It features the door closer body mounted on the pull side of the door and the arm mounted on the door frame.

![]() Top Jamb Installation

Top Jamb InstallationIn the top jamb door closer installation, the door closer body mounts to the top of the door frame and the arm mounts to the push side of the door.

![]() Parallel Arm

Parallel ArmIn a parallel arm installation, the door closer body mounts to the push side of the door, and the arm is connected to a flat bracket that mounts to the bottom of the door frame. This is installation is very popular for door applications that do not have alot of head room above the door.

![]() Tri-Pack Door Closers

Tri-Pack Door ClosersDoor closers are often sold as tri-packs. The term tri-pack indicates that the door closer includes everything needed to install it in a standard installation, top jamb installation, or parallel arm installation.

![]()

Door Closer Types

Surface Mounted Door ClosersA

surface mount door closer is the most popular door closer type. It mounts to the exterior of the door or frame. Surface door closers are mounted standard, top jamb, or parallel arm. Surface door closers are available with a cover or without as shown in the illustration below. Most commercial hollow metal or wood doors use surface mount door closers. They also widely accepted since they do not require any special door prep before installation. They can easily be replaced or added to nearly any commercial door.

![]() Overhead Concealed Door ClosersOverhead concealed door closers

Overhead Concealed Door ClosersOverhead concealed door closers, or often referred to as storefront door closers, are a type of hydraulic door closer that is mounted inside the door frame's channel. Concealed door closers are very popular in storefront doors. The benefit of concealed door closers is that it hides the door closer from the public view.

![]() Floor ClosersFloor closers

Floor ClosersFloor closers are a type of hydraulic door closer that is mounted in the floor. They are popular in the same way overhead concealed door closers are, since they are hidden from public view. Floor closers are ideal for curved doors that are unable to use surface mount door closers. Economically floor closers are the most costly type of door closer due to their size and design. The door closer mechanism is housed in a special enclosure designed to be cemented into the floor. All floor closers are sealed to keep out moisture and rain from penetrating into them. Floor closers also require much more prep work for installation or replacement in comparison to the other door closer types. For all these reasons floor closers are not used as frequently on commercial doors.

![]() Power Door Operators With Self ClosingPower door operators

Power Door Operators With Self ClosingPower door operators, or ADA door openers, is an electromechanical door opening device. During the opening cycle, a dc motor powers the door to swing open, and during the close cycle a closing spring gently closes the door. Power door operators have gained much popularity in the last decade due to the requirements set forth by the ADA (Americans With Disabilities Act.

![]()